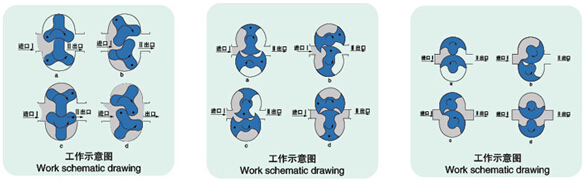

Rotor pump also known as colloid pump, three leaf pump, sole pump, etc. Two rotors (2-4 teeth) with synchronous reverse rotation generate suction (vacuum degree) at the inlet during the rotation, so as to inhale the materials to be transported. The two rotors divide the rotor chamber into several small spaces and operate in the order of a → B → C → D. When running to position a, only chamber I is filled with medium; when position B is reached, part of medium is closed in chamber B; when position C is reached, medium is also enclosed in chamber a; when position D is reached, chamber a and chamber B are connected with chamber II, and the medium is transported to the discharge port. In this way, the medium (material) is continuously transported out.

Almost no wearing parts:

There is no wear of any parts in the rotor pump (except mechanical seal). All parts contacting with materials are made of stainless steel. A pair of rotors operate synchronously in the work, and there is no contact and no theoretical wear. The rotor pump can work in a variety of environments up to 220 ℃.

Water flushing mechanical seal and oil lubricated mechanical seal:

The mechanical seal structure with water washing and oil lubrication functions can be provided to prevent the material from condensing on the end face of the mechanical seal in the process of conveying high viscosity materials, which will affect the normal operation of the equipment, and ensure the service life of the mechanical seal in the dangerous environment.

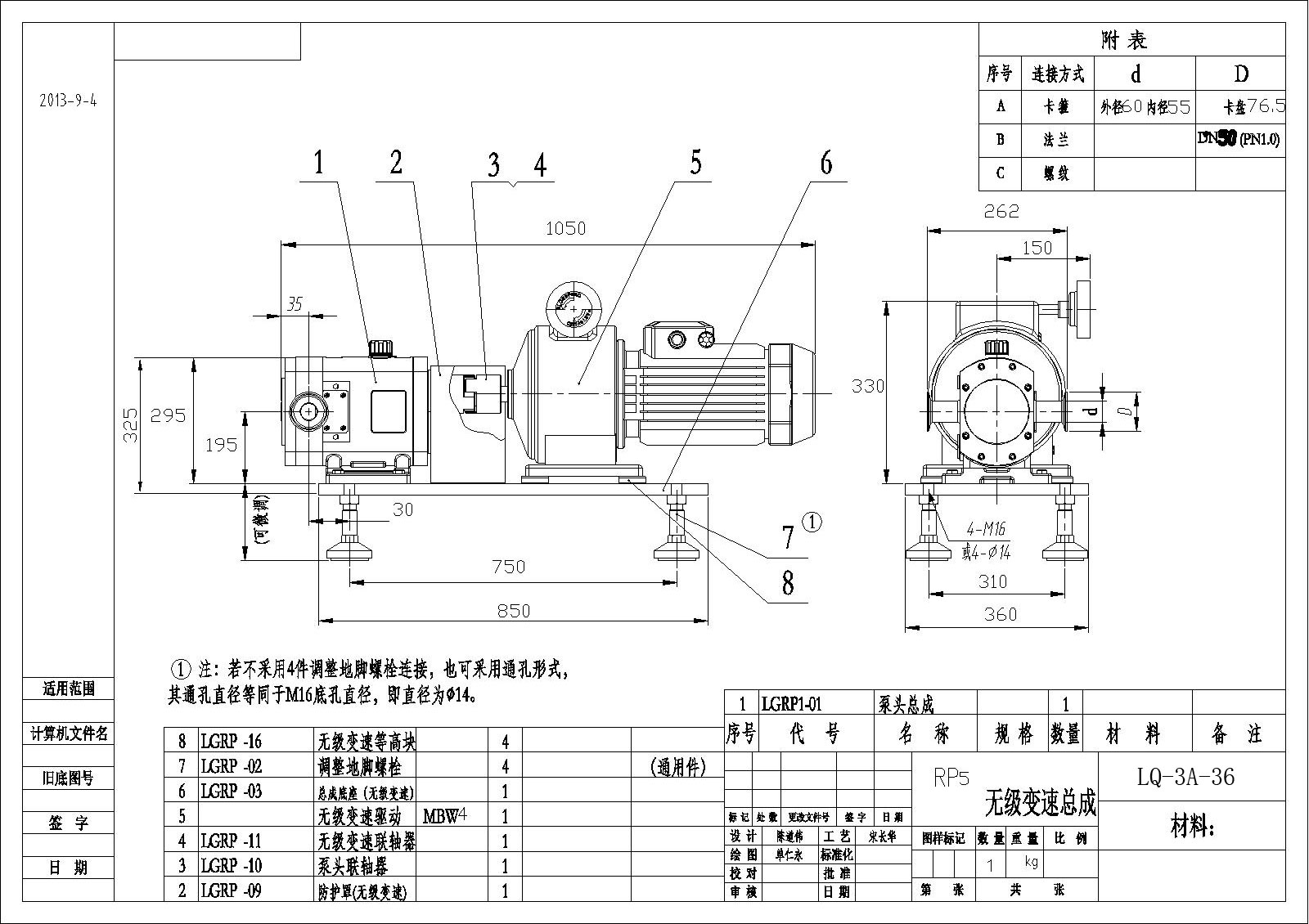

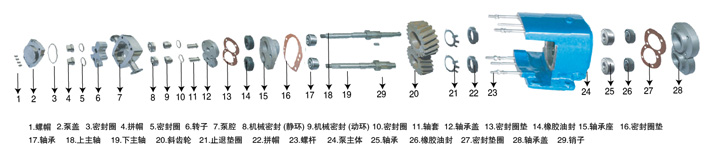

Structural drawing of rotor pump

Rotor type:

Three blade rotor butterfly rotor single butterfly curved rotor

1. Three blade rotor:

The volume efficiency of the three blade rotor is high, and the pulsation is small. For the fluid with general viscosity, the flow rate is relatively large, the pressure is high, and the application range is the widest, but it is not suitable for conveying the fluid containing particles.

2. Butterfly rotor:

Due to the use of butterfly rotor, in addition to the characteristics of general rotor pump, it has certain advantages in conveying materials with high viscosity and large particles, and can effectively transport especially viscous materials.

3. Single butterfly curved rotor (particle rotor pump): 1

This series of pumps are specially designed and manufactured for conveying materials containing large particles. Their unique shape and curve form enable them to have incomparable advantages compared with other pumps in conveying materials containing large particles. In the process of conveying materials, it can effectively avoid particle damage, and is the first choice for conveying materials containing particles.

4. Multi blade rotor:

For the condition of high and stable flow, the multi blade rotor can just play its function, the more commonly used is the five blade rotor, the fluid delivery capacity is relatively stable, because more blades occupy the space of the cavity, and the volumetric efficiency is relatively low. According to customer requirements and actual production conditions, we can provide four blade to twelve blade rotor.

Scope of application

Food industry: sour milk, fresh cream, ice cream, cheese block, whey, beer, wort, yeast, steam gel, hair coloring agent, sesame oil, toothpaste, detergent, shampoo, shoe polish, cosmetics, essence, soap, balsam and so on.

Pharmaceutical industry: various types of pill paste, emulsifier, syrup, nutrient solution, traditional Chinese medicine, paste medicine, biological products, fish pollen, royal jelly, vaccine.

Chemical industry: fat, solvent, resin, polymer, paint, pigment, dye, coating, lubricating oil, grease, petroleum agent, emulsified asphalt, adhesive, plastic, explosive, FRP, leather, etc.

Construction industry: various coatings. It includes interior and exterior wall coatings, anticorrosive materials, ceramic coatings, paint coatings, ceramic glazes, etc.

Other industries: plastic industry, textile industry, paper industry, coal flotation agent, nano materials, biochemical industry and other industries.